THE APPLICATION SUGGESTIONS

Expert Guidance To Meet Your Fluid Control Needs

FLUIDICS APPLICATION

Gas Monitoring Fluidics

Enhance Your Gas Monitoring Instrument with FOREACH Environmental Protection Components

Enhance your gas monitoring instruments with FOREACH’s specialized fluidic components, designed specifically for environmental protection applications. Flue gas monitors play a crucial role in measuring specific gases in emissions from air pollution sources, such as sulfur dioxide (SO₂), nitrogen oxides (NOₓ), carbon monoxide (CO), and carbon dioxide (CO₂). These measurements are essential for confirming that industrial emissions comply with environmental regulations and for providing valuable data to support environmental protection initiatives. By accurately monitoring these pollutants, industries can ensure their operations are more sustainable and environmentally responsible.

Enhance your gas monitoring instruments with FOREACH’s specialized fluidic components, designed specifically for environmental protection applications. Flue gas monitors play a crucial role in measuring specific gases in emissions from air pollution sources, such as sulfur dioxide (SO₂), nitrogen oxides (NOₓ), carbon monoxide (CO), and carbon dioxide (CO₂). These measurements are essential for confirming that industrial emissions comply with environmental regulations and for providing valuable data to support environmental protection initiatives. By accurately monitoring these pollutants, industries can ensure their operations are more sustainable and environmentally responsible.

As flue gas analyzers have progressed from electrochemical detection methods to advanced chemical spectrum detection technologies, their testing capabilities have also expanded. Modern flue gas monitors now conduct multiple types of analyses, necessitating complex, multi-channel fluidic pathways to maintain consistent and accurate results with each test. FOREACH’s fluidic components are engineered to meet these specific requirements, supporting reliable performance in diverse testing conditions and enhancing the accuracy of every measurement.

FOREACH Environmental Protection Capabilities

For Gas Monitoring

- Excellent gas path control capabilities

- Expertise in overall consistency and user experience in fluidic components and instrument use

- Ensure challenges are effectively addressed before they impact your device development

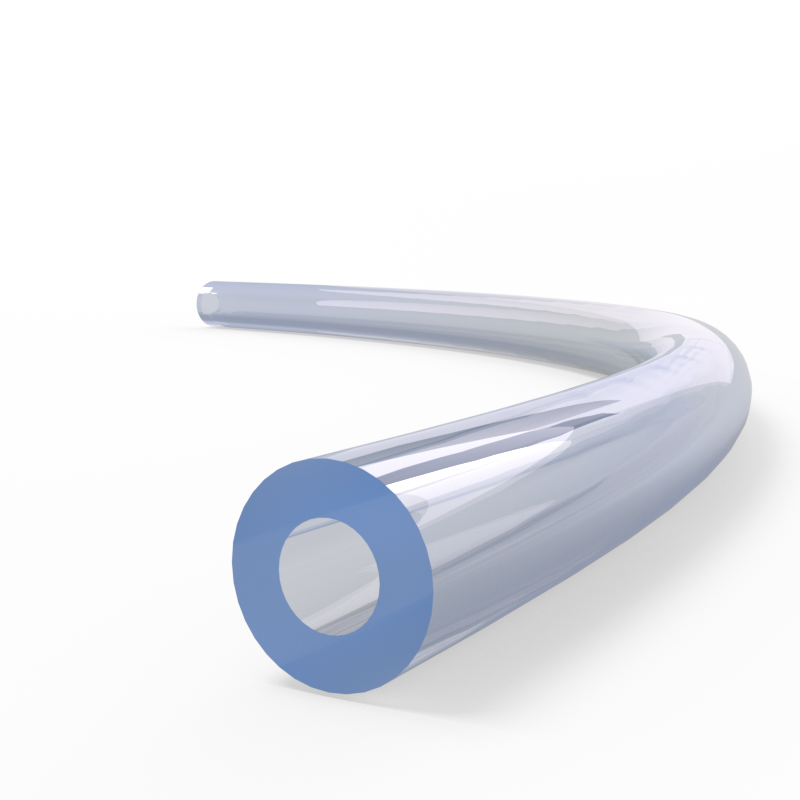

Related Products

When Configuring Fluidics

-

What is the best setup for my fluidic system? Can FOREACH help turn my concept into a functional model? FOREACH’s engineering team, with expertise in fluidic design and applications, can guide you step-by-step to bring your concept to life.

-

How can I be sure that this is the best fluidic design for my instrument? Through computational modeling, FOREACH engineers can verify the reliability of the design, helping you reduce prototyping time, accelerate development, and identify potential risks early on.

-

Why is a pressure sensor essential in these designs? Pressure monitoring is crucial for controlling flow and assessing the stability of the fluid path. FOREACH’s compact pressure sensors easily integrate into your system, providing precise pressure readings throughout the flow path.

-

What role do FOREACH components play in gas monitoring? FOREACH provides a robust fluid control system that ensures precise management of gas paths, essential for meeting environmental emission standards.

-

How does FOREACH address challenges in gas monitoring? FOREACH’s pumps and thermal controllers improve consistency and user experience, effectively managing the fluid path in gas analyzers.

Subscribe for Newsletter

Work with our RD team, Let's make flow easy