THE APPLICATION SUGGESTIONS

Expert Guidance To Meet Your Fluid Control Needs

FLUIDICS APPLICATION

Automated Filling Equipment Fluidics

Enhance Your Automated Filling Equipment with FOREACH Industrial Automation Fluidic Components

The rise of industrial automation is fueling advancements in fluid control systems, which are essential for enhancing the efficiency and reliability of today’s production processes. From precise chemical dispensing to managing complex fluid applications in automatic filling machines, FOREACH’s fluidic solutions meet the needs of diverse industries. In automatic filling machines, precise control of fluid flow is vital to ensure accurate and consistent dosing for a wide range of liquids and viscous substances. FOREACH’s components support high-speed, repeatable filling operations, reducing product waste and ensuring that each container receives the exact required volume. These advanced automation technologies enable manufacturers to optimize performance, reduce waste, and minimize downtime, facilitating a shift towards smarter, more efficient operations that boost productivity and maintain competitiveness in the market.

Aligned with the principles of Industry 4.0, FOREACH provides specialized expertise, collaborative support, and custom solutions tailored to address the unique demands of industrial automation. As more manufacturers implement Industry 4.0 methodologies, the need for reliable fluid control technologies continues to grow across sectors such as industrial inkjet printing, precise lubricant and adhesive dosing, automotive cleaning systems, and commercial equipment. FOREACH’s valves and pumps are engineered for durability and consistent performance, handling applications that involve cleaning agents, reagents, corrosive chemicals, and microwave digestion. Designed to operate under varied concentrations, high pressures, and extreme temperatures, our products deliver top-tier functionality even in the most challenging environments, supporting robust and reliable operations in automated fluid handling tasks.

FOREACH Industrial Automation Capabilities

For Automated Filling Equipment

- Precision and Efficiency. Engineered for precise chemical dispensing and fluid management, FOREACH components optimize performance, reduce waste, and minimize downtime in industrial automation processes

- Industry 4.0 Alignment. Fully aligned with Industry 4.0 principles, FOREACH offers specialized expertise, collaborative support, and custom solutions to address the unique challenges in automated production environments

- Durability Under Harsh Conditions. Designed to handle complex chemicals, high pressures, and extreme temperatures, FOREACH valves and pumps ensure consistent performance, even in demanding environments

- Versatile Application. Suitable for diverse sectors like industrial inkjet printing, lubricant and adhesive dosing, and automotive cleaning, FOREACH components provide reliable fluid control for a wide range of industrial needs

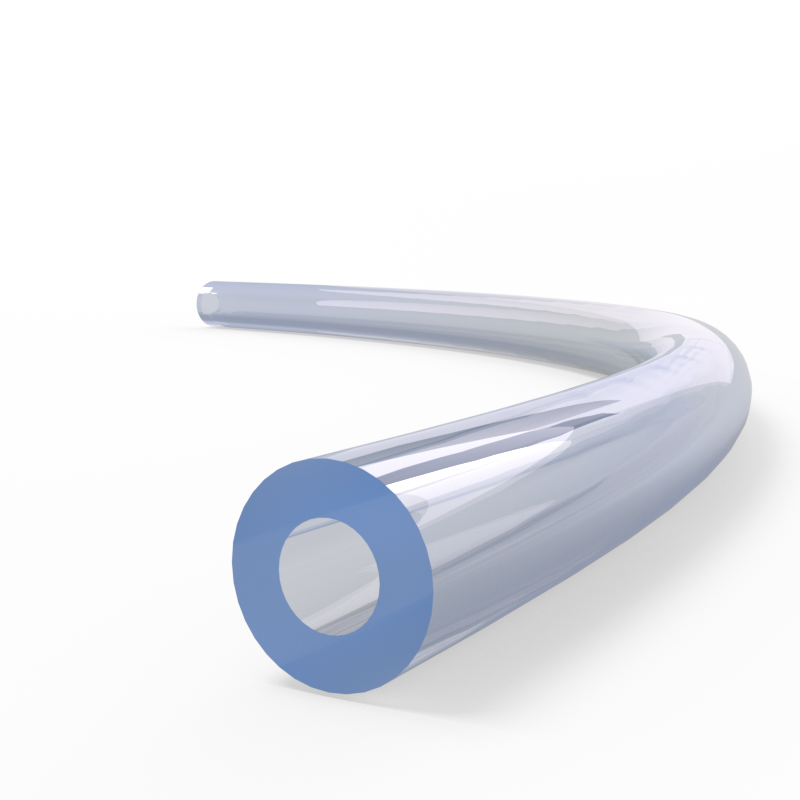

Related Products

When Configuring Fluidics

-

What is the best setup for my fluidic system? Can FOREACH help turn my concept into a functional model? FOREACH’s engineering team, with expertise in fluidic design and applications, can guide you step-by-step to bring your concept to life.

-

How do I know this fluidic setup is the most suitable for my device? Through computational modeling, FOREACH engineers can verify the reliability of the design, helping you reduce prototyping time, accelerate development, and identify potential risks early on.

-

Why is a pressure sensor essential in these designs? Pressure monitoring is crucial for controlling flow and assessing the stability of the fluid path. FOREACH’s compact pressure sensors easily integrate into your system, providing precise pressure readings throughout the flow path.

-

How do FOREACH fluidic components facilitate industrial automation? FOREACH’s precision pumps and valves optimize fluid handling in industrial processes, reducing waste and enhancing operational efficiency.

-

How does FOREACH meet Industry 4.0 standards? FOREACH’s customized solutions align with Industry 4.0 standards, supporting automation needs through reliable fluid control technology.

Subscribe for Newsletter

Work with our RD team, Let's make flow easy